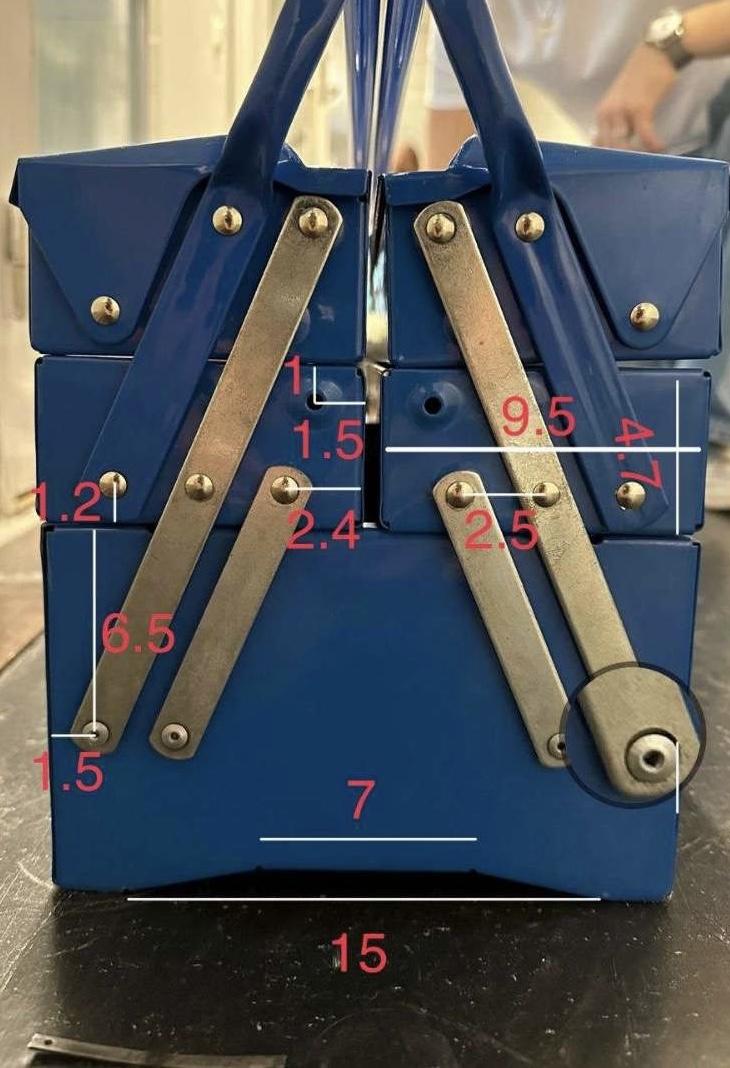

Could someone please provide me with resources to complete my cantilever toolbox CAD assignment? I need to create a CAD design similar to this example: [https://www.sealey.co.uk/product/5637183402/530mm-4-tray-cantilever-toolbox]. I’m new to CAD and don’t know where to begin, so any guidance would be greatly appreciated. My plan is to create one large box and four smaller boxes (copy past 3 times or mirror), then assemble them together. I’ve already completed one large box and one small box, but I’m finding the next step quite confusing. (For this we are using solidedge in school).

Hello Teeshk Nader. Before starting any project, it is important to determine its purpose. Are you working on a training exercise or trying to improve your skills? If so, that's perfectly fine and there's nothing personal about it. However, if the project is intended for mass production, the designer needs to be aware of the materials being used and the company's capabilities to produce them. This will ensure that the final product is of high quality and can be produced efficiently.

Ohh, it’s for a school assignment (cad submission). So probably it’s a “training exercise or trying to improve your skills”? And i also want to learn for later use.

Hi Teeshk

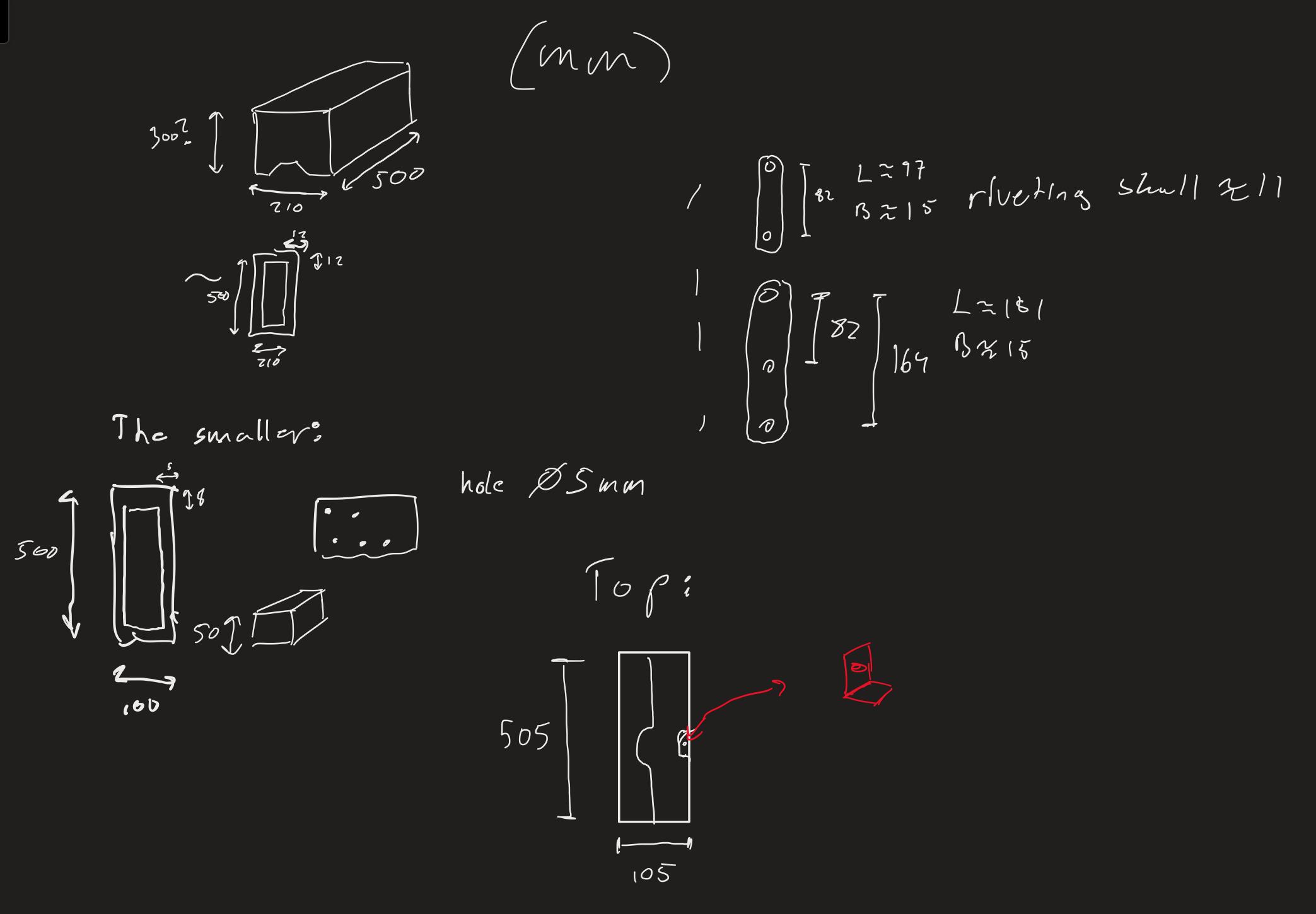

this is probably one of most easy sheet metal project consist of two different size box and one type handle. First design boxes and handle as a sheet metal part file, then only remain define mates for assy. Its not complicated that make you confuse at all.

You did not shared dimensional details so only I assume for example you may choose sheet metal thicknes as 1 or 1.5 mm. Steel. Toolbox finished complete assembly dimensions in closed position width 300 mm height 300 mm and length 600 mm for example. First step is done now you have a enough data to start your design, next step is define part dimensions. you will divide assy dimensions in to parts dimensions .. for example assy height is choosen 300mm you have one bottom box and two tray boxes then 300/3 = 100mm each height. Then you have bottom box (Main box) dimensions as might be width300*height100*length600; Smiliar you can have small box dimensions will be W150*H100*L600. on the top you will design one cover. Weak spot of design is you should try to design everything symmetric. I mean you design one cover for two top tray and one small box for 4 tray and one hinge for all connections and one handle part will be used together when toolbox is closed.

According to your sample design shall be consist of 6 part and bolt-nut connections.

Would this help:

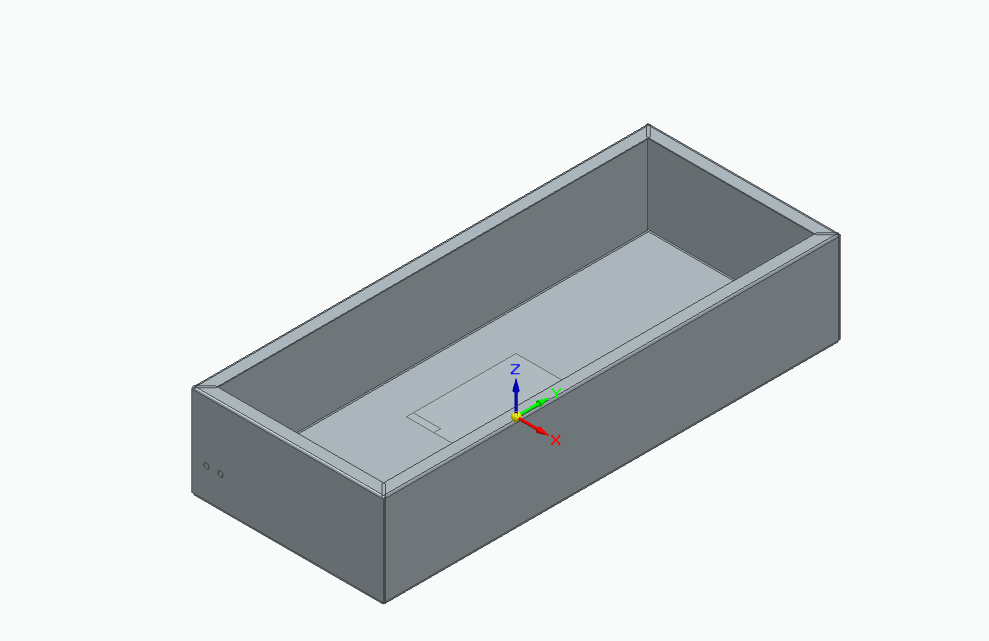

IF you're completely new to SolidWorks I would suggest to ignore the sheet metal part of the design and start with simply modeling all the parts with all holes and features needed and creating assembly, later you can show use what you got and we can show you how to turn it in to actual sheet metal parts

technically for student especially , I am not giving fish instead teaching how to fishing..

you have all resources to accomplish this project believe me if you start you shall finish only some small touches remain so you can find support . . . but this is not support someone accomplish your study project.

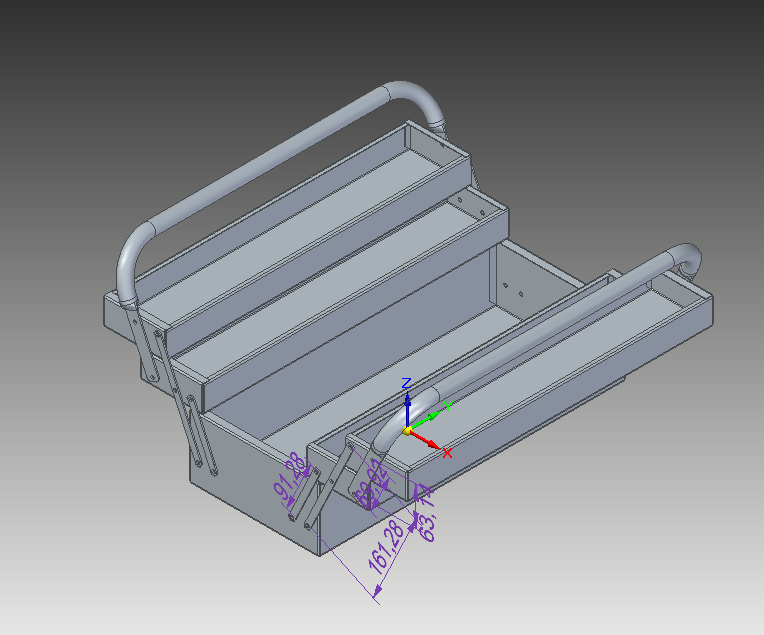

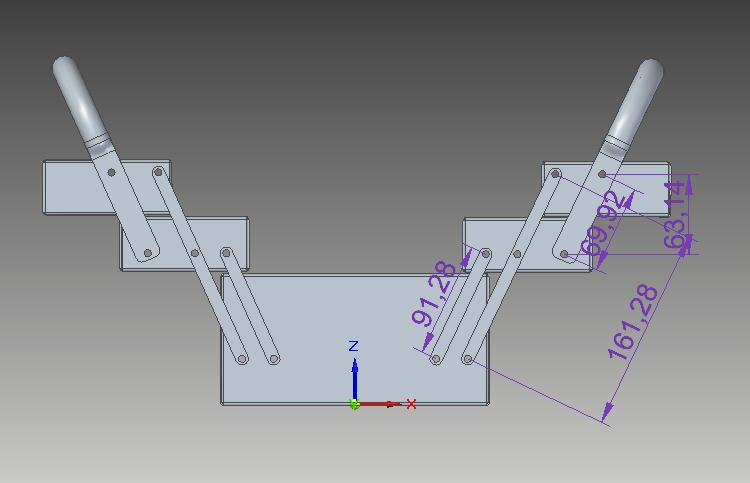

I have made it this far:

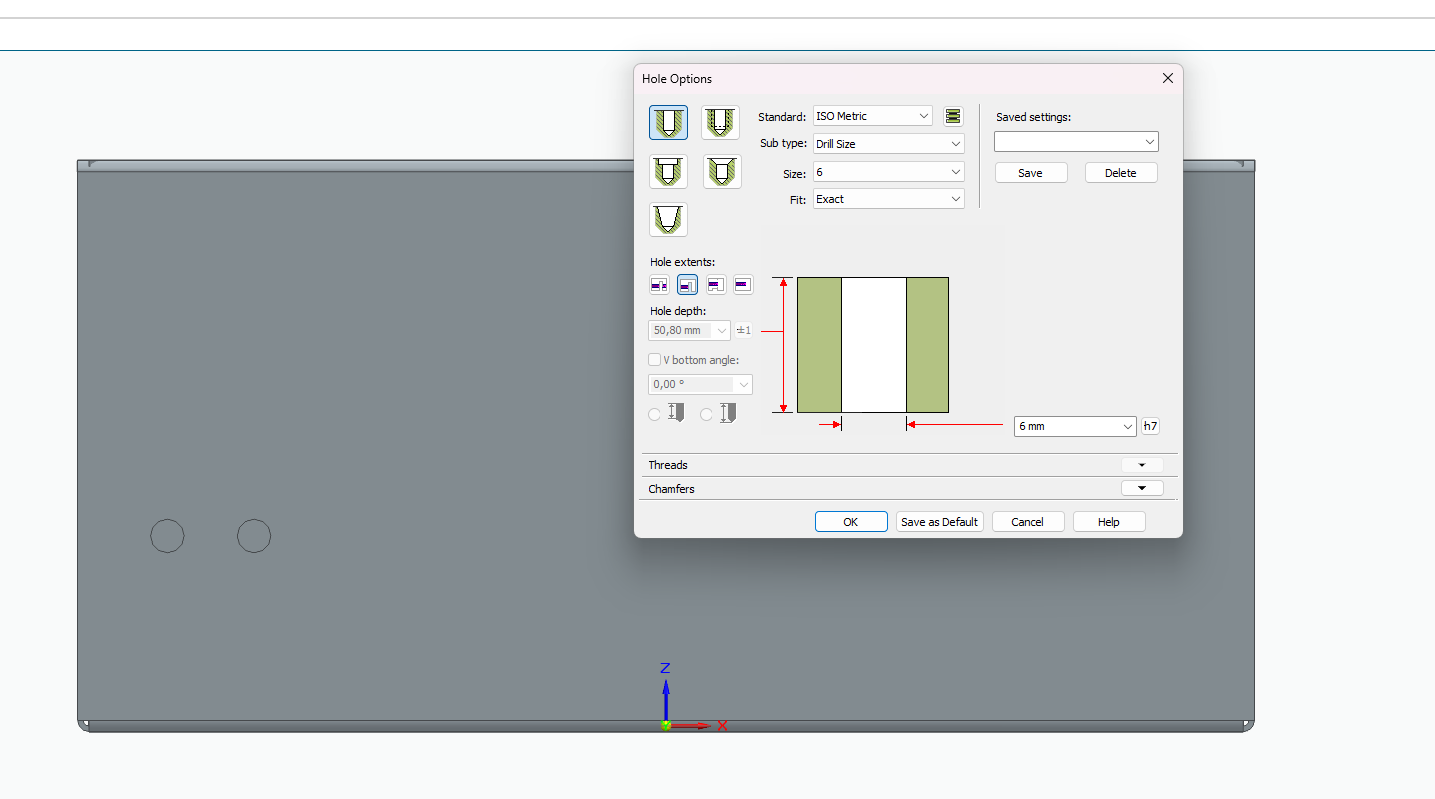

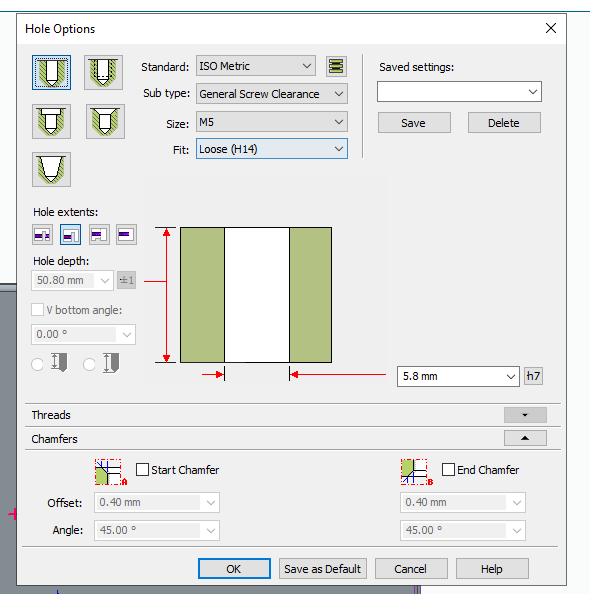

I have problems with the holes. Dont know the places i should make a hole and which hole options i should use:

Should i assemble the boxes first and then make the holes?

Hi Teeshk,

You are lucky , because normally I’m so busy , but I appreciate your effort. You are well done. I believe you will accomplish this project with success. I see you have come half way and it seems to only remain to go the other half to finish. I will show you the path..

You can solve your hinge mechanism with an appropriate model.. You can apply a here very basic parallelogram , four-bar linkage mechanisms.. This is the simplest closed-chain movable linkage.

If you don't know what it is , I am leaving an information link here..

https://ocw.metu.edu.tr/pluginfile.php/6885/mod_resource/content/1/ch7/7-1.htm

Also, you can ask uncle Google 😊

We may proceed with the Autocad 2D design.

Why? .. because I am only trying to show you the path, not how to walk.. If you understand logic, so the same method you able to be apply by Solidworks or an inventor or any other cad program

First, this is my toolbox, so I assumed boxes 300x150 and 150x100 mm.

“ This is only a displaying method. Do not stick on dimensions. . You may arrange them according to your design later.”

2. Defining block

We changed the upper box into a block to make our studies easy and also we will apply 3 connection points in block editor mode. I assumed 50mm is enough between for each connection point at middle level height.

I defined 3 connection point as shown in drawing

“ İf you don't know how to create a block, I explain,

First choose lines, arc circles etc. and CTRL-x Cut, then CTRL Shift Paste as a block.

This is the most easiest way to create a block on AutoCAD”

Our drawing is has become more convenient with the upper box block.

3. Defining box positions in open and closed state

I assumed that the upper box , while located upper box at 125 mm away from the closed state, it s providing enough gap to take something from the box or put something in it.

4 . Define link lengths and pivot points.

We will open our upper box block in block editor again. Trial and error method may use to define appropriate linkage lenghts or simple assume 150 mm half length of our box height w emay choose to see what we will have..

When block editor closed our drawing give us a connection points.

To find a pivot point, only draw a line from the center of the yellow circle to the intersections and to define the second point, we may apply the same method from the center of the first green circle and intersections of green circles.

5 . Optimisation

As shown in last drawing, the bottom box pivot point is too high and length linkage length are too short. We need to extend them to make a mechanism, turn in more easy operable state.

Radius extended 50 mm to obtain 150mm in block editor mode.

After turning in back to drawing mode, now we get two more different pivot point positions.

What we are doing here is trying to optimise relation between pivot points and linkage length.

You can find a sample in the Wikipedia link below to understand how much variation may be drawn in this mechanism.

https://en.wikipedia.org/wiki/Four-bar_linkage#/media/File:4bar_curves.gif

As shown in drawing, red lines are too short according to the green lines and neglecting thus First stage linkage length obtaining from Green line length.

6. Defining the upper box connection point and second stage linkage length.

We will define another block at the same dimensions as the first box, but connection points will not be the same because the second box has got a longer radius, thus following a different trajectory while opening and closing.

according to drawing second stage linkage obtained 110 mm lenght.

7. Drawing linkage bar

Now we have enough data to draw linkage bars as shown

150mm hinge is obtained from first stage

110 mm hinge is obtained from second stage

260mm hinge is obtained from multiplying first and second stage

Ps. hinges designed as sheet metal.

8. Accomplish Assy with applying linkage bars in to drawing.

To refine drawing, seperate open and closed states

As you see our tool box trays are working betwween Open and closing postion

İf you got how to apply this method into simple four linkage bar mechanism, it means

Now you can also design this;

. (metro train door mechanism)

Or you you can design this;

. (Bus luggage door)

Or you can design this

all of them are working on same four linkage mechanism rules.

instead of everything if again you stuck on somewhere; let me have a look your design..

2 questions:

2 questions:

How do i make a design for the top?

How do i make a M5 bolt nut:

lets talk about First question those M5 bolts. You need Mushroom head square neck bolt.

This kind of bolts usually using on sheet metal and wood constructions. As its name this is self lock bolt so no need to screwdriver or wrench to tighteen. Please note that , bolt end is square shape so you must be open square cut on your sheet metal according to bolt end size and on other sheet metal part must have hole according to standart M5 bolt..

here I am leaving link so you may have a look bolt's standart details

https://www.fasteners.eu/standards/DIN/603/

also You can downlaod 3d model from trace parts and link is here;

https://www.traceparts.com/tr/product/mushroom-head-square-neck-bolt?Product=10-11062001-216999

you will need a standart M5 bolt and washer to accomplish bolting assy. I am leaving other links here also;

I reccomend torque type Nut it doesnt loosen in time,

DIN 985 Bolt Prevailing torque type Nut; you can download from here;

https://www.traceparts.com/tr/product/d%C4%B1n-hexagon-nut-d%C4%B1n-985-m5-x-08-10?CatalogPath=TRACEPARTS%3ATP01001007009&Product=10-11062001-133256&PartNumber=DIN%20985%20-%20d%20M5%20x%20p%200.8%20-%2010

or alternatively you may use standart nut but you must apply anti loose washer.

DIN 934 Standart Nut, you can download from here;

https://www.traceparts.com/tr/product/d%C4%B1n-hexagon-nut-d%C4%B1n-934-m510?CatalogPath=TRACEPARTS%3ATP01001007009&Product=10-11062001-160766&PartNumber=DIN%20934%20-%20d%20M5%20-%2010

self locked washer for DIN 934 Standart Nut, you can download from here;

https://www.traceparts.com/tr/product/hobson-nordlockr-standard-washer-m5?CatalogPath=TRACEPARTS%3ATP01001017004003&Product=10-01072020-064277&PartNumber=WNHTDDM05

And your second question about top cover , but sorry

I did not get what you mean?

I think, cover is not complicated more than boxes..

Mate, This is your own desing and those tool box pictures are for reference so you dont need to copy and paste everything in to your model. You are free to make changes or modifications that you want.

According to me you only need to start a new sheet metal part design and let it finish.