Hello, I need your help for my project,

I want to design a motor controlled valve, I tried many times but I can't do exactly what I want in terms of water leakage. I would be very happy if you have any suggestions...

Thank you .

https://grabcad.com/library/dil-valf-v6-1

*******************************************************

*************************************************************

*******************************************************

"water leakage" as water bypassing the valve or water leaking outside the valve ?(with your current design probably both ?)

why not use any of commercially available valves and just figure out how to attach and operate it with your motor ?

lookup "gate valve" or "actuated butterfly valve" for some ideas

if you really want to start working on this design and not change it for a commercial system (it would be indicated), I recommend looking at the sealing systems between the brown-purple, blue-purple and brown-blue pieces, where there are types of polymers that can help to close (o'ring), in addition, depending on the materials to be used if they can withstand the pressure exerted by the fluid (if it is necessary to reinforce the joint with more bolts or change of material) so that it does not deform them neither plastically nor elastically and finally appreciate the vibrations (if they are present).

There are few question.

Hello Nejat DURMUS,

I must agree with the rest of my colleagues in recommending using commercial valves, which have long since refined their design and corrected their errors, providing great reliability.

In any case, if you want to continue with your development, I would recommend changing the format of the closing plate so that it contains both the part that closes and the part that gives way to the fluid. In this way the sealing can be done on its two flat faces (using suitable O'rings or V'rings).

And a second opportunity for improvement is to simplify the drive by making it directly circular (which is much simpler, more reliable and more durable than the mechanism for linear motion).

I hope these opinions are useful.

Greetings!

Hello Marcelo Valderrey

Hello Nejat Durmus,

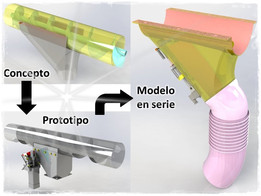

I don't know the tea making process, but I have had to work with ground coffee moving through screw conveyors to their storage silos. For the discharges they used commercial valves similar to the ones you are designing. But, when they were closed and the coffee circulated through the screw to another silo, they had a "dead space" that filled with coffee and compacted, preventing its circulation when said valve was opened again. So, they asked me to design a "no dead space" valve that could be inserted into the 90 drops from the screw conveyors to the silos. You can see the process and final result in this model (and others related to its construction):

First I made a handmade prototype that was installed for a long time as a test, and then I designed a model for low-series construction (100 units) that follows the same concept, but with various construction changes.

Kind regards!

where are the seals to prevent the leakage?