The SPL concept introduced a novel approach by exploiting natural pressure differentials between ground level and stratospheric altitudes to drive a piston for ejection. This eliminated the need for stored energy systems, resulting in a lightweight, modular, and easily manufactured design. The submission was supported by thorough analysis, modeling, and prototyping, with careful consideration of all flight phases from prelaunch to release. The originality of the concept, combined with its robustness and feasibility, set it apart as the top entry.

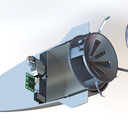

The CO₂-powered ejection mechanism offered a compact, manufacturable, and low-complexity approach to capsule separation that directly addresses key limitations of current SPEED concepts. By leveraging an off-the-shelf pressurized gas source, the design balances simplicity with reliability across all phases of operation. The submission also accounted for environmental effects and system behavior under realistic conditions. At the current test scale, safety and handling concerns are minimal, though application to larger vehicles may introduce additional certification challenges.

This entry used lightweight, 3D-printed and laser-cut components to create a compliant spring system. While somewhat larger in volume, the design remained simple, manufacturable, and easy to assemble. A compact, well-designed trigger mechanism distinguished the concept from other spring-based submissions and demonstrated reliable functionality.

The Knuckleball Ejection Mechanism demonstrated a practical spring-based system refined for manufacturability, ease of integration, and reliability. The design incorporated a non-invasive retention method, reusable loading tools, and straightforward scaling through commercial components. Verification and validation were particularly strong, including prototyping, ground testing, and detailed cost analysis, which provided confidence in its robustness under flight conditions. While evolutionary rather than radically new, the thorough execution and demonstrated feasibility distinguished this entry.

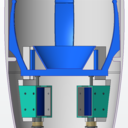

The solenoid-driven mechanism emphasized simplicity, minimal part count, and straightforward manufacturing. The design provided a reliable electromechanical release triggered by the avionics suite and supported feasibility with analysis and modeling. Though somewhat bulkier and heavier than other solutions, the concept offers clear opportunities for optimization. Its cost-effectiveness, robustness, and ease of assembly made it a strong and practical submission.